Add to Cart

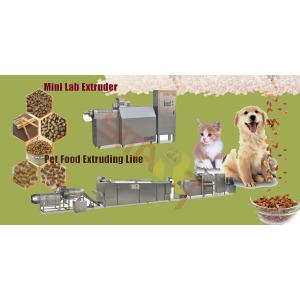

200kg/h Automatic Dry Dog Food Making Machine

Introduction:

1,Pet Food Double Screw Extruder has balancing the components and gentle processing are at the center of the related quality considerations.

2.Pet Food Double Screw Extruder is therefore increasingly proving to be the right tool for modern Pet food. A complete feed, fed as a diet over a prolonged period of time, must ensure the vitality of the animal and prevent deficiencies.

3.Pet Food Double Screw Extruder is quite a challenge to the feed manufacturer in terms of the selection and composition of the raw materials, their optimal processing, and effective quality assurance.

4.Pet Food Double Screw Extruder constitute the biggest market segment.

5.Pet Food Double Screw Extruder has high-grade complete feeds capable of maintaining the health even of exotic species in aquariums over prolonged periods of time, sinking or floating feed.

Raw Materials: Adopts soya meal, fish meal, bone meal, rice bran etc. As raw materials.

Dog Kibble Food Machine Flow Of Chart:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine.

Main Parts Of Dog Kibble Food Machine:

Technicial Parameter

| Model | DR-65 | DR-70 | DR-85 | DR-90 |

| Capacity | 120-150kg/hr | 200-300kg/hr | 500-600kg/hr | 800-1000kg/hr |

| Power | 80kw | 90kw | 150kw | 200kw |

| Dimension | 18 x 5 x 3m | 20 x 5 x 3m | 35 x 5 x 3m | 40 x 5 x 3m |

Standard Configuration

| Item | Brand |

| Motor | WEG or Siemens |

| Electric Parts | ABB or Schneider |

| PLC and Touch Screen | Siemens (controls whole line, not one or two single equipment) |

| Bearing | NSK |

| Materials | cover body, mesh belt and parts touching with raw materials or final products are stainless steel |

Dog Kibble Food Machine Machine Features:

1.high capacity and Long service life

2.The cutting structure is very advanced. It has such outstanding features as novel design,

unique, simple structure,easy to installation and unloading, easy operation, etc .

3.There is a special pressure increased device to ensure the quality and the capacity. Besides,

the Electric heating device improve the feed expansion rate.

4.steam methord floating fish feed pellet machine :Starch gelatinization can reach 90% to

furtherly increase the feed capacity.

5.The high temperature in the extrusion chamber (max. 160 Celsius) in accordance with

the needs of customers.

This temperature is necessary to remove the urea of the enzyme in soybeans, extending

the shelf life of rice bran, cotton seed or detoxification.

6.The fish feed pellets can float in water for about 24 hours. It is very catering and easy to

be digested for animals, especially fish.

We Provide Satisfied service and Turnkey Solution

A. Free consultation service before, during, and after sales;

B. Free project planning and design services;

C. Free installation and commissioning of equipment until everything is functional;

D. Free management of equipments' long distance shipping;

E. Free training of equipment maintenance and operating personally;

F. Free new production techniques and formulas;

G. Provide 1 year complete warrantee and life-time maintenance service;

H. Engineers available to service machinery overseas.

I. Provide technical exchanging

A. Finished time

The production line will be finished in 25-40 days after confirmation.

B. Payment Term

30% is paid by T/T as the down payment, 70% is paid by T/T or L/C before shipment.

C. Delivery Time

When the machines are finished, we will invite you to our factory for testing machine.

then we will arrange the worker to load container promptly after all corresponding inspection issues finished.

Video:

Smart plant: